Glass drilling is primarily used to create round or custom-shaped holes in glass surfaces for installation, ventilation, or decorative purposes. Due to the fragile nature of glass, conventional drilling methods often cause cracks or breakage, requiring specialized technology and equipment. Glass drilling is widely applied in architecture, home furnishings, industrial equipment, and artistic glass products.

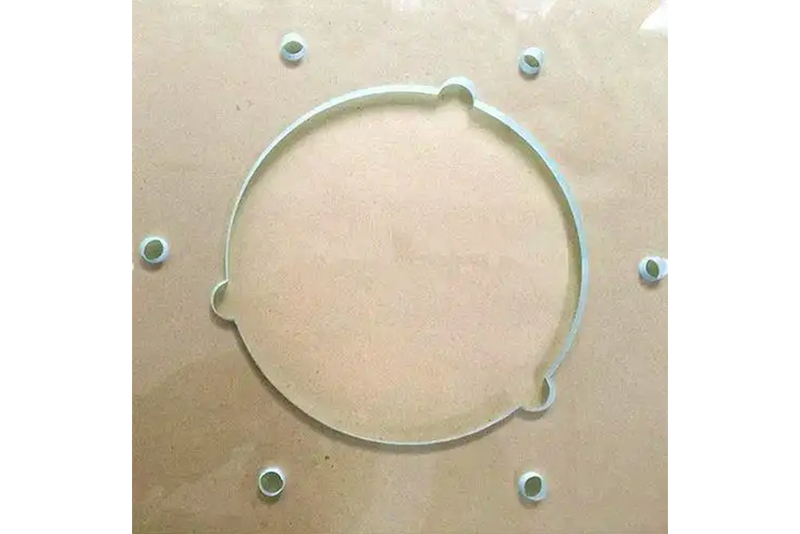

Our mirror laser drilling machine, manufactured by Aolite Laser, utilizes advanced laser technology to outperform traditional drilling methods. Laser mirror drilling is a high-precision, non-contact process that is easy to operate and capable of meeting complex and intricate requirements.

Our mirror laser sandblasting machine, produced by Aolite Laser, uses advanced laser technology to replace traditional sandblasting methods. It achieves clean, precise, and uniform surface textures without damaging the reflective layer of mirrors.