Glass drilling is primarily used to create round or custom-shaped holes in glass surfaces for installation, ventilation, or decorative purposes. Due to the fragile nature of glass, conventional drilling methods often cause cracks or breakage, requiring specialized technology and equipment. Glass drilling is widely applied in architecture, home furnishings, industrial equipment, and artistic glass products.

Glass drilling is primarily used to create round or custom-shaped holes in glass surfaces for installation, ventilation, or decorative purposes. Due to the fragile nature of glass, conventional drilling methods often cause cracks or breakage, requiring specialized technology and equipment. Glass drilling is widely applied in architecture, home furnishings, industrial equipment, and artistic glass products. Examples include:

Architectural glass façades for installing fixtures;

Home glass doors or partitions for mounting handles or hinges;

Industrial equipment for custom observation windows or instrument panels;

Artistic glass items for achieving special design effects.

Our glass laser drilling machine, manufactured by Aolite Laser, utilizes advanced laser technology to outperform traditional drilling methods. Laser glass drilling is a high-precision, non-contact process that is easy to operate and capable of meeting complex and intricate requirements.

Advantages of Glass Laser Drilling:

High Processing Efficiency

The laser drilling machine delivers high-peak laser pulses, releasing large amounts of energy in a very short time. This allows for rapid processing and, when integrated with automation, supports large-scale production.

High Precision

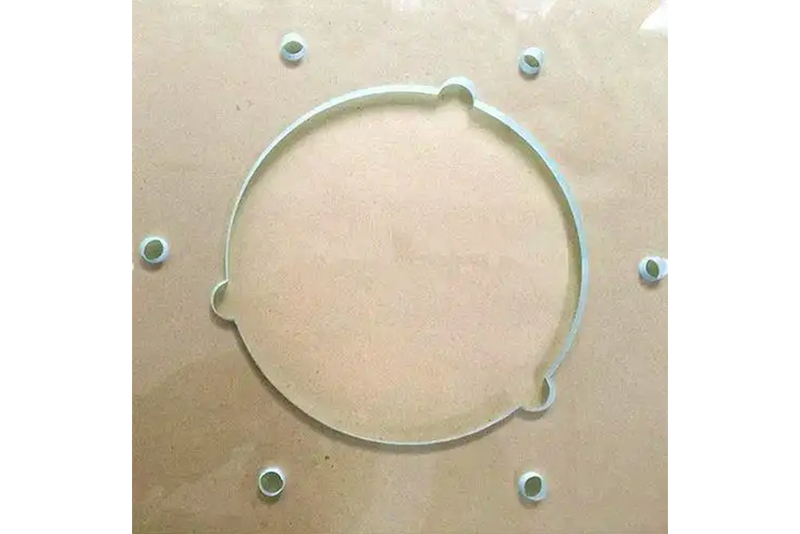

By precisely controlling the energy of each laser pulse and using a small focused spot, it achieves fine, accurate glass processing. It can handle both standard holes and complex custom shapes with ease.

High Stability

With short pulse durations and minimal heat-affected zones, the laser minimizes thermal impact on surrounding areas of the glass. Its non-contact operation avoids mechanical stress or surface wear, ensuring consistent and high-quality results.

Unlimited Creative Flexibility

Any pattern can be processed without templates, edited digitally, and produced on-demand, making it ideal for personalized and customized designs.

This machine is also widely used for drilling, roughening, paint removal, and marking on a variety of glass types, including float glass, optical glass, microcrystalline glass, conventional soda-lime glass, architectural glass, and high-borosilicate glass, meeting diverse processing requirements across industries.